How DoseRx1 Works:

1) Standardised Cartridges:

DoseRx1 uses Quality controlled and refillable cartridges. The cartridge contains the necessary formulations to produce a variety of doses. Insert the SEA 316L stainless-steel cartridge and select the dose you would like to produce. The DoseRx1 dose manufacturing process is versatile, enabling true 3D printing using Semi solid formulations, liquid based dispensing, and molding. This versatility ensures a large range of compatibility with >80% of oral API’s.

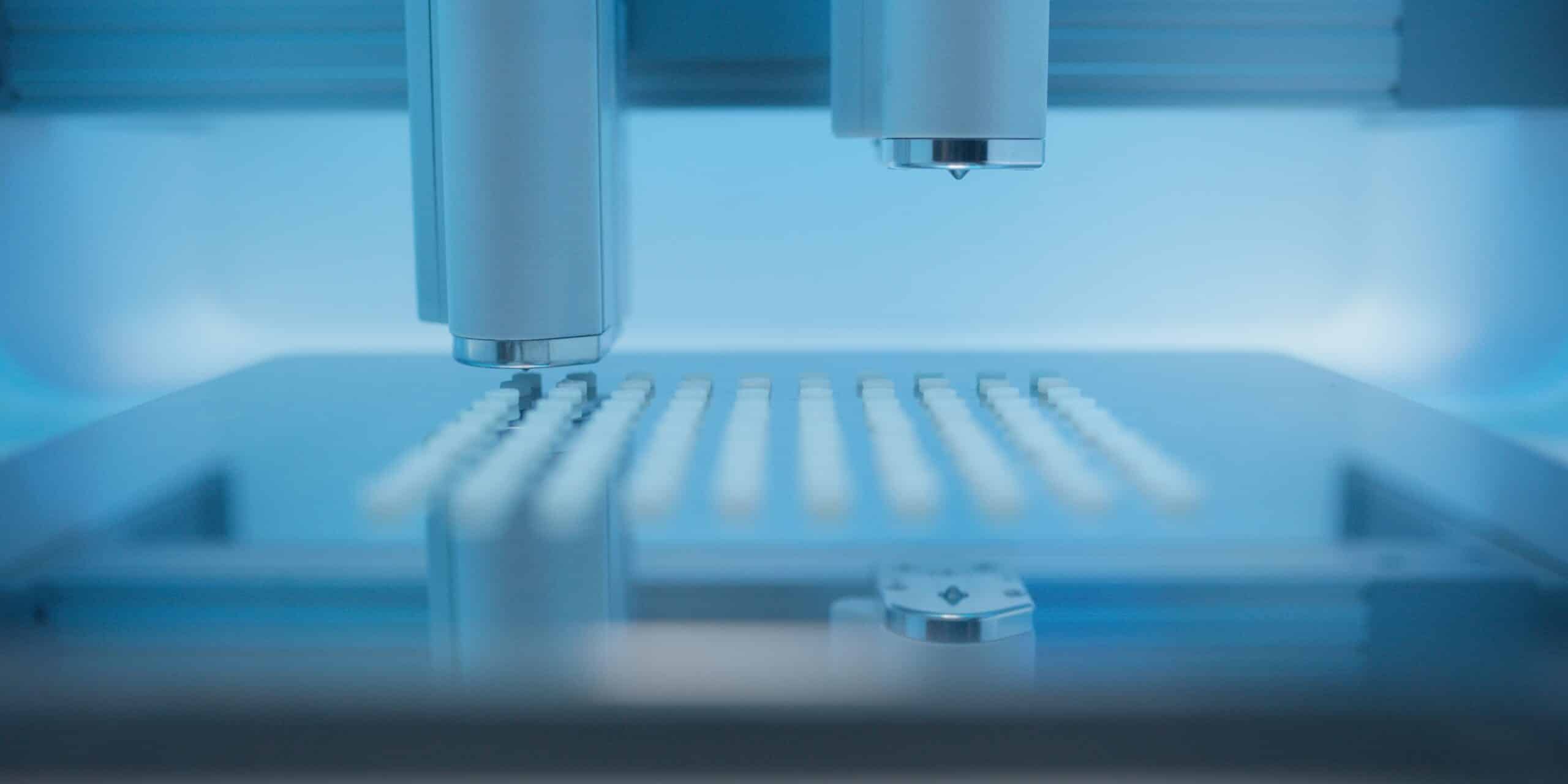

2) Printing:

Enter the required dosage and number of tablets needed for the patient. This can be done through a user-friendly interface on the touch screen. Print to 100 to 1000 doses per hour.

3) GMP-Proof:

The DoseRx1 is designed with Good Automated Manufacturing Practices in mind. This ensures that we can provide documentation for the printer to be qualified in any GMP environment.

is4) Semi Solid Extrusion technology and formulation IP:

Highly accurate SSE technique enables printing at low operating temperature or at room temperature This protects the active ingredients and results in an incredible range of suitable products. DoserRx1 enables printing, dispensing and molding, unlocking >80% of oral medication available today! This in contradiction to any laser-based 3D printing or filament based technology.

5) Easy to clean:

Pharmacists know that cleaning hardware used for compounding is highly important in avoiding cross contaminations of APIs, especially with equipment for powder-based products. As the printer is designed for GMP environments, you will see no obscured parts or hidden crevices. This ensures maximum cleanability. The smoothly curved panels with coated metal ensures quick and proper cleaning after each print and the print bed can be removed. This enables fast switching between different batches of medicines easily.